What is a Spring Machine?

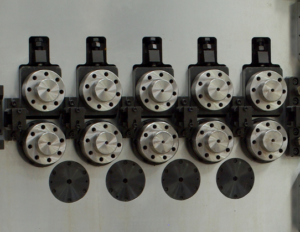

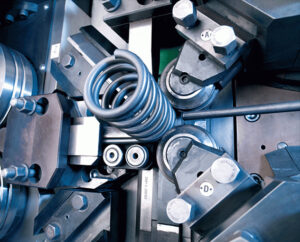

A spring machine is a specialized tool used to manufacture various types of springs, such as compression, tension, and torsion springs, as well as wire-forming products. It operates using computer numerical control (CNC) systems and precision servo motors to produce high-quality springs with a variety of shapes and sizes.

A spring machine helps industries such as electronics, automotive, and appliances produce durable and precise springs, improving both efficiency and quality.

Spring machines play a crucial role in industries requiring high-precision springs. The benefits of using a spring machine go beyond simply mass-producing springs—it ensures accuracy and repeatability in production, reducing human error. Many modern spring machines are equipped with advanced CNC systems and can handle complex wire-forming tasks.

What is the Spring Machine Used For?

Spring machines are primarily used to manufacture different types of springs, such as compression, tension, and torsion springs. These are essential components in products across various industries like automotive, electronics, and household appliances.

Spring machines can also form wire into other shapes and components, including washers, coils, and specialty parts. Some advanced models even produce complex shapes for custom applications, like those used in high-tech gadgets or specialized mechanical devices.

Spring machines are versatile tools that streamline the production process and ensure high-quality springs for different industrial applications.

The machine adjusts settings based on wire diameter, length, and other parameters to create the required spring with utmost precision. This ability to customize the springs’ properties ensures that they meet the specifications of the design, whether for heavy machinery or delicate electronics.

What is the Cost of a Spring Machine?

The cost of a spring machine varies depending on its features, size, and complexity. Basic machines may start at a few thousand dollars, while advanced models with multi-axis capabilities and automation can cost tens of thousands of dollars.

Investing in a spring machine is crucial for companies that need reliable, consistent, and high-quality spring production. The price depends on factors like machine type, number of axes, and its additional features like automatic wire feeders.

For instance, a simple 4-axis spring machine might cost around $20,000, while a 12-axis machine with advanced features and larger capacity could go up to $100,000 or more. Buyers should consider their production needs to choose the right machine that balances cost and functionality.

Is There a Machine to Make Spring Rolls?

While "spring rolls" and "spring machines" share the word "spring," they are entirely unrelated in function. Spring rolls are a popular food item, while spring machines are tools for manufacturing metal springs. There is no specific "machine" for making spring rolls in the industrial sense.

The term "spring machine" in this context refers to machines used in the production of metal springs, not food products like spring rolls.

However, food industry machines do exist for preparing spring rolls, such as automated cooking and rolling machines used in commercial kitchens. But these machines are not connected to the types of spring machines used in manufacturing mechanical springs.

What Does a Spring Maker Do?

A spring maker operates or supervises the operation of spring machines, ensuring that the machinery is correctly set up to produce the desired spring types. They are responsible for adjusting machine settings, loading materials, and overseeing the production process.

Spring makers play a vital role in industries requiring customized or high-precision springs, ensuring quality control and efficient production.

In addition to operating the machines, spring makers may also be involved in designing the springs, selecting the appropriate materials, and conducting inspections to ensure that each spring meets the necessary standards. They are critical in industries like automotive manufacturing, electronics, and even the production of medical devices.

Conclusion

Spring machines are essential for industries that rely on high-quality, precision springs. By automating production, these machines improve efficiency, reduce errors, and enable the manufacturing of complex spring designs.