What is a Spring Coiling Machine?

Spring coiling machines are essential in producing various types of springs, used in everything from electronics to automobiles. But what exactly makes these machines so critical in spring production?

A spring coiling machine is a CNC-based tool designed to create different types of springs from wire by winding it around a mandrel. These machines can be complex, with capabilities that range from simple coiling to advanced multi-axis operations for precise shaping.

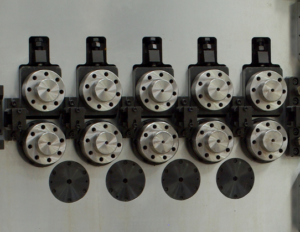

CNC8680

CNC8680

Spring coiling machines are widely used for creating compression, tension, and torsion springs. Depending on the design, they can operate in 2-axis, 3-axis, 5-axis, and even 6-axis configurations, each with different benefits and use cases. The advanced models of YF spring coiling machines stand out for their ability to handle wire diameters ranging from 0.15 mm to 16 mm, offering a solution for both small and large-scale production.

What is the Process of Spring Coiling?

The process of spring coiling begins with wire feeding and shaping. A precise and controlled approach is essential for ensuring the accuracy and durability of each spring produced.

Spring coiling machines shape metal wire into specific forms, depending on the intended use. These machines use a variety of processes like winding, bending, and cutting, which are controlled by sophisticated computer systems.

What types of spring presses are available in Yinfeng

When you look at the process in detail, each step involves high precision to meet various specifications for industries like electronics, toys, automobiles, and more. For example, a YF 2-axis machine, typically the most affordable, is capable of producing simple compression springs and basic wire bending. In contrast, a 5-axis camless machine can create more complex shapes, improving production speed by up to 35% and allowing for greater flexibility in the shapes it can produce. This distinction is crucial for manufacturers who need both efficiency and variety in their spring products.

Comparison Table: 2-Axis vs 5-Axis Spring Coiling Machines

| Feature | 2-Axis Machine | 5-Axis Machine |

|---|---|---|

| Wire Diameter Range | 0.15-0.8 mm | 0.15-0.8 mm |

| Production Speed | Basic, slower | 35% faster than 2-axis |

| Flexibility | Limited to basic shapes | Can produce complex shapes |

| Cost | Least expensive | Higher due to advanced features |

| Typical Use Case | Compression Springs | Complex, shaped springs |

CNC8212 VS CNC8512

CNC8212 VS CNC8512

What is the Cost of a Spring Coiling Machine?

The cost of a spring coiling machine can vary significantly depending on the number of axes and the capabilities required.

Spring coiling machines range from affordable 2-axis models to high-end 6-axis machines. Factors influencing price include wire diameter capacity, the complexity of the spring produced, and the speed of production.

While a 2-axis machine might be more budget-friendly, prices for more complex models like the 5-axis or 6-axis machines are higher. For instance, a 2-axis machine capable of handling wire diameters from 0.15 to 1.2 mm can be purchased at a relatively low price, typically making it suitable for mass production of simpler springs. On the other hand, 5-axis machines, known for their higher speed and ability to shape complex springs, are priced higher. Manufacturers seeking to produce custom, shaped, or high-precision springs might opt for these advanced machines despite the higher upfront cost due to long-term productivity benefits.

Comparison Table: 3-Axis vs 6-Axis Spring Coiling Machines

| Feature | 3-Axis Machine | 6-Axis Machine |

|---|---|---|

| Wire Diameter Range | 0.3-3.0 mm | 0.3-16.0 mm |

| Production Speed | Effective for single-product mass production | Faster with flexible model changes |

| Cost-Effectiveness | Ideal for mass production | Higher cost but more versatile |

| Debugging Time | Standard | 40% faster debugging |

| Flexibility | Suitable for basic designs | Can develop more complex spring types |

CNC8645

CNC8645

What Machine is Used to Make Springs?

Machines used for spring manufacturing are usually categorized by their number of axes and their capabilities. Whether it’s a compression, tension, or torsion spring, there’s a specific machine type to fit the job.

Machines like the YF 2-axis, 5-axis, and 6-axis models are commonly used for making springs. These machines provide the precision and efficiency required to produce high-quality springs for a range of applications.

The YF spring coiling machines, for example, come in different configurations, offering a range of features such as automatic wire feeding, precise cam angle control, and servo motors for high-speed production. The 2-axis machine is perfect for simpler compression springs, while the 5-axis and 6-axis machines allow for a greater variety of spring shapes, making them indispensable for industries requiring highly complex spring designs. The 6-axis machines are particularly popular for their ability to change models quickly and debug settings faster than their 3-axis counterparts.

What is the Difference Between Winding and Coiling?

While winding and coiling both involve the looping of wire, there are distinct differences between the two processes, particularly when it comes to spring production.

Winding refers to the simple act of wrapping wire around a central point, while coiling involves more complex and controlled shaping, often producing springs used in mechanical applications.

The main difference lies in the precision and flexibility of the process. Coiling, especially when done with advanced machines like those from YF, involves multiple movements, including bending and twisting the wire, to create various types of springs. Winding, on the other hand, is a more straightforward process and is typically used for basic wire forms. A YF 2-axis machine, for example, uses simple coiling techniques for standard compression springs, while more advanced 5-axis machines can handle more intricate designs, capable of adjusting wire paths and angles for customized shapes and sizes.

Conclusion

Spring coiling machines are crucial for a wide variety of industries. Whether you need simple compression springs or complex, custom-designed ones, there is a machine configuration suited to your needs.

For more information about our machines and to explore the full range of YF spring coiling machines, visit our product page.