How to Choose the Right CNC Spring Machine?

Spring production problems can ruin deadlines, quality, and budgets. Picking the wrong CNC spring machine makes everything worse.

The right CNC spring machine helps you produce high-quality springs faster, more consistently, and with less waste. It supports your business growth by improving reliability and performance.

Choosing the right CNC spring machine isn’t just about specs. It’s about knowing what your production line needs today—and what it might need tomorrow. Let’s break down what really matters.

Why CNC Spring Machines Matter for Your Business?

Cheap spring machines break down. Inaccurate ones create scrap. Complex ones cost too much to run. That’s the real pain.

CNC spring machines boost accuracy, flexibility, and speed, helping you meet customer demands while keeping costs down.

The Competitive Edge of CNC

A good CNC spring machine gives your business a serious edge. Here’s how:

Precision and Stability

YF’s CNC machines use servo motors from Japan and Taiwan. That’s why they feed wire precisely (±0.01mm) and bend with tight angle control (±0.10°). The result? Springs that always match spec.

Flexibility for Multiple Industries

Whether you’re producing for toys, electronics, automotive, or even hair accessories, CNC spring machines can switch between jobs easily. You don’t need multiple setups—just load a new program and go.

Lower Downtime, Higher Productivity

YF machines store hundreds of processing programs. If you’re switching between jobs often, that matters. Less time setting up = more time producing. And with features like automatic wire break detection and wire rack acceleration, production keeps moving.

| Feature | Benefit |

|---|---|

| Multi-axis control (2–13) | Supports complex shapes |

| Automatic wire break stop | Prevents waste |

| CN/EN interface | Easy for operators |

| Max. Speed: 100m/min | Fast output |

| Spring types | Tension, torsion, pagoda, swirl, wire forms |

What Makes a CNC Spring Machine Stand Out?

Lots of machines look the same. But some quietly outperform the rest.

Great CNC spring machines combine control, speed, precision, and smart automation—all in one machine.

What to Look For in a Standout Machine

Not all CNC machines are created equal. Here’s what separates the best from the rest:

Axis Count & Control System

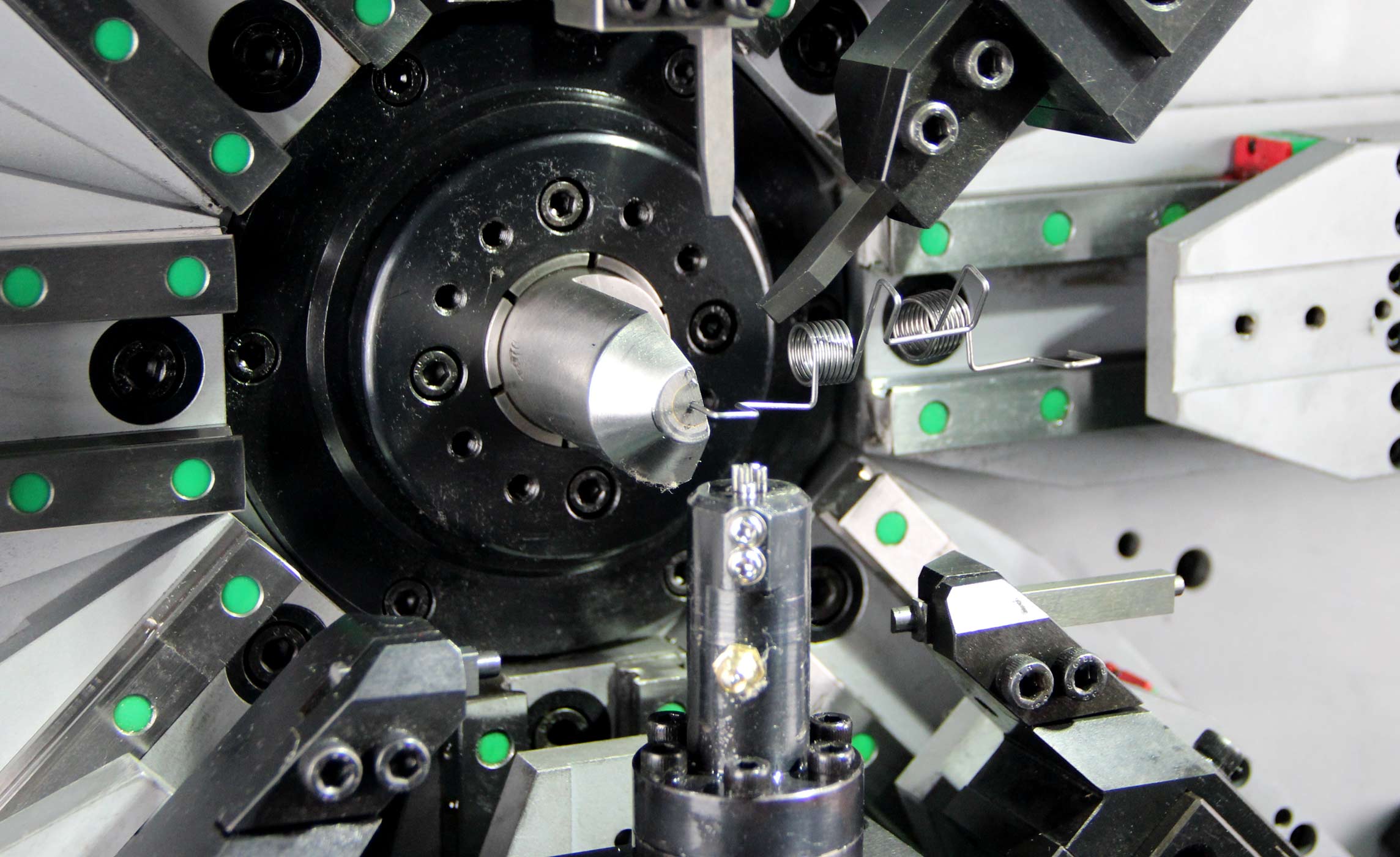

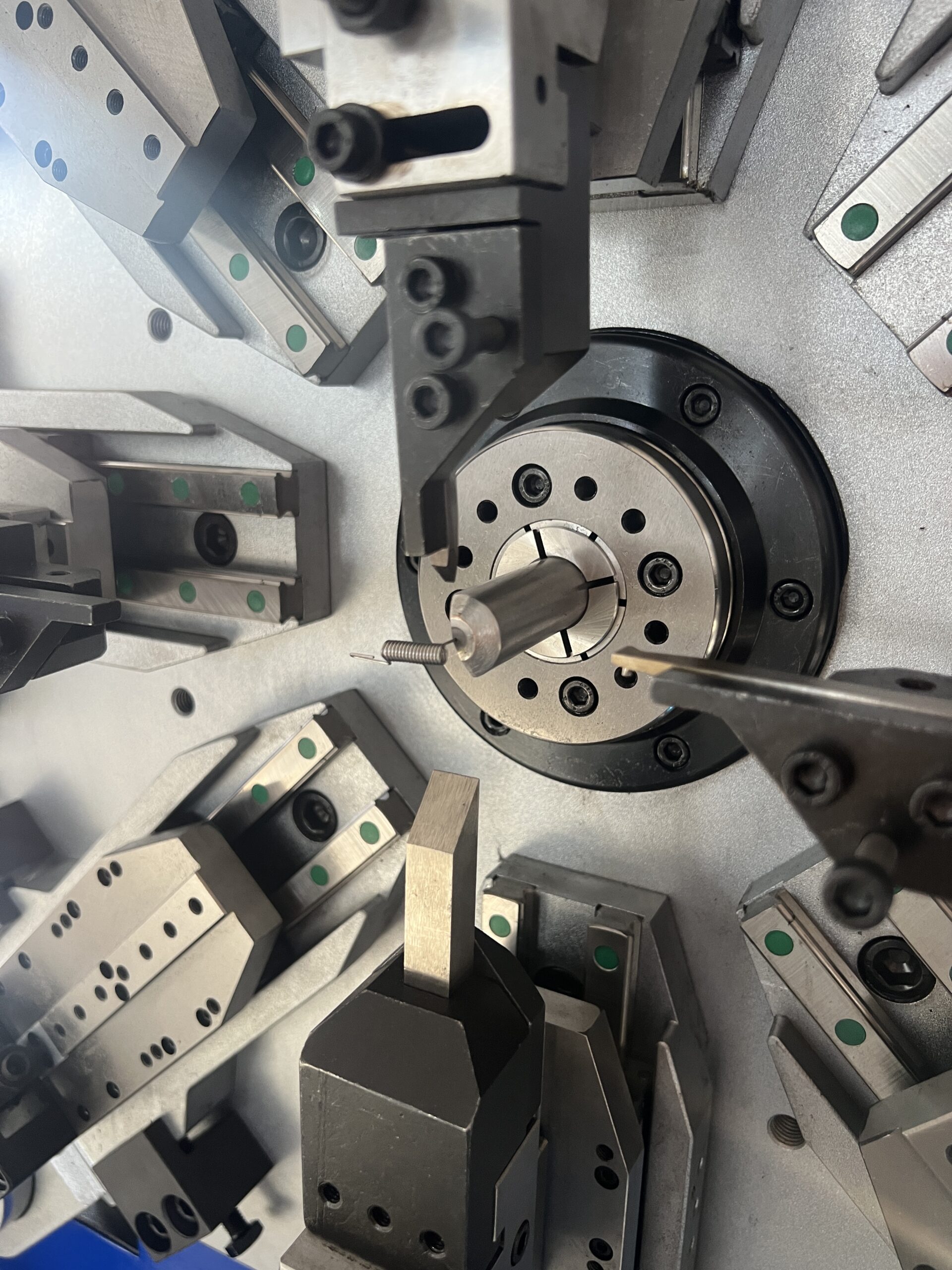

The more axes, the more complex shapes you can create. YF’s machines range from 2 to 13 axes. The 12-axis camless models use independent servo motors. That means they form even the most complex springs fast and reliably.

Cam vs. Camless Design

Camless machines like the YF-12 series are faster to debug and offer higher positioning accuracy. Fewer moving parts also mean longer machine life and less maintenance.

Real-Time Adjustments & Detection

Machines like YF’s offer real-time monitoring. That means if a spring is off-spec, it stops. You fix the issue before wasting material. Also, the system lets you tweak diameter or angle while the machine runs.

| Machine Feature | Why It Matters |

|---|---|

| Camless Design | Faster setup, less wear |

| Multilingual Interface | Easier for global teams |

| Smart Probes | Auto-detect spring quality |

| Servo-driven Feed & Bend | Smooth, stable motion |

Why Choose Our YF CNC Spring Machines?

You’ve got choices. But only one machine keeps your production running smooth with every spring.

YF CNC spring machines are engineered for precision, reliability, and easy operation—backed by 20+ years of proven results.

What Sets YF Machinery Apart

I’ve worked with other brands. Many start strong but slip over time. YF machines hold up—thanks to a strong foundation of technology, service, and support.

Proven Technology

YF uses servo motors from Japan and Taiwan. Their machines feature rigid, high-precision wire feeding, stable cam movement, and sleek design. You’ll notice the difference in every spring.

Built for Every Spring Type

From 2mm tension springs to 14mm heavy-duty coils, YF’s machine range covers everything. Need 3D wire forms? Try the 7-axis 3D wire bending model. Need to produce compression and torsion springs with tight tolerances? The 12-axis camless model gets it done.

Long-Term Support

YF doesn’t just sell machines. They provide setup help, technical training, and fast support. Their “Technology first, quality win, service intimacy” approach isn’t just a slogan—it’s how they operate.

| Machine Type | Wire Diameter | Axis Count | Best For |

|---|---|---|---|

| YF-7A 3D Bending | 3–8mm | 5 | Complex 3D forms |

| YF-12 Camless | 1–6mm | 12 | Precision & speed |

| YF-3 Axis | 0.2–2.5mm | 3 | Basic coils |

| YF-6 Axis Compression | 1–4.5mm | 6 | Medium springs |

| YF-13 Axis Full Auto | 0.8–3.5mm | 13 | High-volume, complex |

Conclusion

Choosing the right CNC spring machine means more speed, fewer errors, and better profits—YF makes that easy.